STANDARDS OF PRACTICE

The International Standards of Practice for inspecting the roof system is located at www.nachi.org/sop.

MASTERING ROOF INSPECTIONS

To learn about inspecting asphalt shingle roofs, please visit Mastering Roof Inspections.

DESIGNED TO SHED

Asphalt shingles are designed to be layered. And the layering is designed to shed water. An asphalt shingle roof is designed to be water-resistant -- not waterproof. A shingle roof essentially relies on the slope of the roof to shed the water.

REINFORCED

Asphalt shingles are reinforced. They are referred to either "organic-reinforced asphalt shingles" or "glass-fiber-reinforced asphalt shingles." Most of the shingles in the North America are "glass-fiber reinforced."

Observation

There were two layers of asphalt shingles observed on the roof.

According to 2015 IRC R908.3, when a roof is replaced it should include the removal of the existing layers of roof coverings all the way down to the roof deck sheathing. There are exceptions. If there is an ice barrier membrane adhered to the deck, it may remain in place and covered with an additional membrane layer.

Re-Roof Permitted

A new roof may be installed over an existing roof covering where any of the following conditions exist:

- the new roof covering is installed in accordance with the manufacturer's installation instructions

- the new roof covering does not rely on the existing roof covering for structural support

- metal panel, metal shingle, and concrete and clay tile roof covering may be installed over existing wood shingle/shake roof

- a new protective coating over an existing spray polyurethane foam roofing system is permitted without removing existing roof coverings

Re-Roof Not Permitted

A re-roof (or installation of a second layer of roof covering) is not permitted where any of the following conditions exist:

- the existing roof is water soaked or has deteriorated so much that the material can not perform as a reliable base for an additional covering

- the existing roof is slate, clay, cement, or asbestos-cement tile

- the existing roof has two or more layers of roof covering of any type already installed

- roof structural system is unable to support the additional load

Observation

There is a small missing piece of shingle. It was not installed. Located near the rake edge.

Observation

There are several shingle of a different color, style and size. The colors do not match, which is a cosmetic issue. However, it is also an indication that incorrect shingles were installed. The shingles also appear to be the incorrect size. Irregular offset patterns of the shingles are indicated.

Near the skylight, the DWV pipe, the furnace vent, and inside the valley, there are many shingles that are 3-tab shingles, which is a type of different shingle. This is a defect.

Observation

There are some shingles that appear to be installed backwards, with the non-laminated section of the shingle being exposed.

Observation

There are many areas on the roof where the shingles are not layered properly. These shingles near the skylight are not installed properly.

Observation

There are cut marks on a couple shingles. This may have been caused by a roofing contractor cutting over the existing shingles. Does not appear to be more than a cosmetic observation.

OFFSET PATTERN

The asphalt shingles should be installed with an offset pattern according to the shingle manufacturer's installation recommendations.

Observation

The are not installed in an offset pattern as recommended by the shingle manufacturer.

FASTENERS

Fasteners for asphalt shingles must be galvanized steel, stainless steel, copper or aluminum roofing nails, minimum 12-gauge shank with a minimum 3/8-inch-diameter nail head.

Observation

There is an exposed nail head at the left-side area.

Observation

There is an exposed nail head observed within the valley. There should not be any exposed nail heads.

Observation

There is an exposed nail head near the skylight.

Observation

There exposed nailing lines on some shingles. This indicates that the amount of shingle exposure is too large. And the nailing line is exposed. These shingles are not installed properly.

Observation

There are shingles that have missing fasteners. They are loosely laying on top of the roof, including this shingle at the left-side, near the head wall.

Observation

Missing fasteners at the shingle to the left of the vent pipe penetration.

Observation

Missing fasteners at the shingle near the gutter end.

NAIL PENETRATION

The fastener should be long enough to penetrate through the roofing materials, and at least 3/4 of an inch into the roof sheathing. If the sheathing is less than 3/4 of an inch thick, the nail should go through the sheathing.

Observation

It is very difficult to see the fasteners from the other side of the roof sheathing. It may be visible from the attic access area.

SLOPE

Asphalt shingles should be used only on roofs that are 2:12 or greater in slope. Asphalt shingles should not be installed on roofs with slopes less than 2:12. For roof slopes from 2:12 to up to 4:12, a double layer of underlayment should be applied.

Observation

The slope of the roof sections on either side of the valley is around 3.4:12.

For slopes 2:12 up to 4:12, the underlayment should be two layers applied with a 19-inch strip of underlayment felt parallel to and starting at the eaves. Starting at the eave, applied 36-inch-wide sheets of underlayment, overlapping successive sheets by 19 inches.

The underlayment is beyond the scope of the home inspection. I am unable to observe the underlayment.

Slope vs. Pitch

Home inspectors should use the term "slope" when describing the roof slope. To learn more about the difference between "slope" and "pitch," visit www.nachi.org/roof-slope-pitch.

UNDERLAYMENT

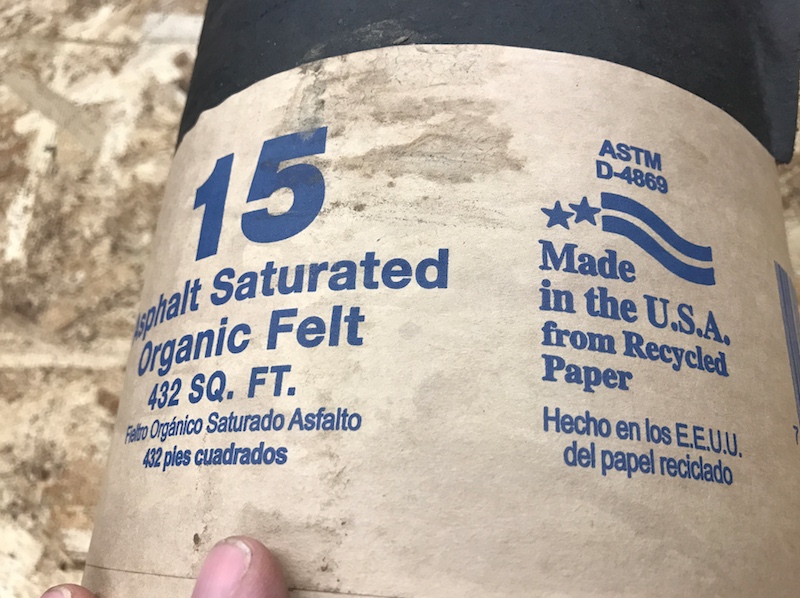

Observation

The underlayment is asphalt saturated organic felt complying with ASTM D-4869 standard. According to 2015 IRC R905.2, the underlayment for asphalt shingle can be ASTM D-4869, Type I, #15 for winds under 140 mph.

For slopes 2:12 up to 4:12, the underlayment should be two layers applied with a 19-inch strip of underlayment felt parallel to and starting at the eaves. Starting at the eave, applied 36-inch-wide sheets of underlayment, overlapping successive sheets by 19 inches.

For slopes 4:12 or greater, underlayment is one layer applied in a shingle fashion, parallel to and starting from the eave and lapped by 2 inches. End laps should be 4 inches and offset by 6 feet.

KICK OUT FLASHING

Observation

The kickout flashing is not installed properly. Its positioned too far up the roof. Refer to the kickout flashing at the other roof section to observe a properly installed kickout flashing.

Observation

The fastener is a common joist hanger nail. The flashing fasteners are typically common roofing nails.

FLASHING

Observation

The step flashing is not installed with the top layer of shingles. The step flashing was left in place with the original layer of shingles. This allows water to run in between the two layers.

Observation

The flashing at the intersection between the roof and the wall is not installed properly.

There is a missing row of shingles that should be covering the fasteners. The dabs of roof sealant is not permanent.

And the flashing is not installed properly. The flashing at the headwall should be installed on top of the top layer of shingles. The flashing is still in its original position, which is allowing water to drain below the roof shingle layer.

Observation

The flashing around the vent pipe is in poor condition. The flashing was not installed with the new top layer of roof covering. It is still installed with the original layer of shingles, which allows water to penetrate into the roof covering and travel between the two layers.

Observation

The vent pipe should be extended upwards above the roof surface at least 6 inches. The vent pipe here is very short.

Observation

The vent pipe is not flashed properly. It was only sealed.

Observation

The collar flashing around the gas exhaust vent pipe is installed upside down.

VALLEY

Valley Inspection Information

Observation

The shingles in the roof valley are not installed properly. There are many major defects.

Observation

In areas of the valley, there are indications I observed that the shingles are not installed properly at all.

The common types of valleys are open, closed, cut and woven. This layer of shingles represents none of those. This valley is unreliable and prone to water intrusion leading to roof leaks.

Observation

There is apparently some plastic sheeting installed in between the layers of shingles at the valley area. This is not a recommended installation for this material. It is an indication of poor installation.

Observation

There are fasteners installed within the valley itself. This is a major defect.

A common recommendation is to restrict all fasteners within 6 inches of the valley centerline.

Observation

SKYLIGHT

Observation

There are loose shingles around the skylight. Missing fasteners at shingles.

Observation

There are loose shingles around the skylight. Missing fasteners at shingles.

Observation

The interior window pane of the skylight has cracked apart and most of it is missing.

Observation

The fasteners at the skylight are not installed properly.

Observation

There are missing fasteners.

Observation

They are not installed tightly. They are not rust-resistant. There are bent nails.

Observation

There are holes in the flashing and frame of the skylight. There are roofing nails being used to fasten the skylight.

Observation

The skylight flashing is loose.

Observation

There are indications that the skylight metal flashing was modified at the installation site. This is another indication at the skylight was not installed according to the manufacturer's recommendations.

Observation

The left-side of the skylight is missing flashing components.

Observation

There's duct tape being used at the flashing area.

Observation

There are 3-tab shingles installed to the left of the skylight. The shingles are of a different type of shingle originally installed on the roof. This is improper and makes this area unreliable. This may indicate a patch on the roof made by a homeowner or unprofessional contractor. Major defect.

Observation

There are indications of torn shingles installed around the skylight. This is an indication of improper installation or poor workmanship.

Observation

The skylight was not installed in alignment with the rows of shingles or the edge of the roof. The skylight frame itself is slightly off square and turned several degrees clockwise.

10 STEPS TO PERFORMING A ROOF INSPECTION

There are ten steps to performing a roof inspection on an asphalt shingle roof.