Standards of Practice

The International Standards of Practice for inspecting the electrical system is located at www.nachi.org/sop.

Free, Online Course

To learn more, take InterNACHI's free, online How to Perform Residential Electrical Inspections Course.

Note:

All wire sizes are American wire gauge (AWG) copper conductors.

Service Drop

Observation

The system is fed from electricity stolen by tapping into the service entrance conductors inside the soffit.

Inspectors should be aware of conditions that indicate that the service entrance conductors have been tapped into before the meter in order to steal electricity.

WEATHERHEAD

Observation

Weatherhead should not be metal on a PVC mast.

Observation

Tape markings on conductors at the weatherhead do not correctly identify the phase and neutral conductors.

Observation

Black- phase (120-volt) conductor.

Red- phase (120-volt) conductor.

White- Neutral conductor.

The neutral (white-taped) conductor should be located in the middle hole of the phenolic insulator.

Mast

Observation

The riser (mast) is made of PVC (polyvinyl chloride).

It should be made of:

i. intermediate metal conduit (IMC);

ii. rigid metal conduit (RMC, commonly called "rigid"), not

iii. polyvinyl chloride (PVC) or

iv. electro-metallic tubing (EMT).

Electric Meter

Observation

Meter enclosure (metal box) is rated for 135 amps, but should be rated for a minimum of 200 amps.

The meter enclosure should not have a rating less than the service main disconnect.

Observation

Missing locknut at nipple in meter enclosure.

Observation

The grounding bushing inside the meter enclosure is not grounded (no grounding conductor attached).

Note: Bonding jumpers are required to bond around reducing washers, and/or oversized, concentric, or eccentric knockouts which are considered to be impaired connections.

Observation

The load side lugs of the meter are double-tapped (to feed the generator inlet).

A double-tapped lug is one in which two conductors are inserted into a lug designed to accept only one conductor. Inspectors should mention double taps for two reasons:

- Lugs are typically not designed to accept two conductors, and this condition may create a poor connection that can lead to overheating and the resulting risk of fire.

- The component fed by the double tap may not be protected by an overcurrent device. This is true in this example.

Observation

Service entrance Conductors (SEC)

No conductor identification markings (colored tape) at either load or line side of meter.

The phase (hot) conductors should be marked with red and black tape, and the neutral should be marked with white.

Observation

The phase (hot) conductors should be marked with red and black tape, and the neutral should be marked with white.

Observation

Observation

The #1 (150-amp) copper service entrance conductors (SEC) installed between the service splice and the meter are undersized.

For a 200-amp service, the service entrance conductors (SEC) should be 2/0 (rated at 200 amps).

Observation

Observation

The #2 (125-amp) copper service entrance conductors (SEC) installed between the meter and the service panel are undersized.

For a 200-amp service, the service entrance conductors (SEC) should be 2/0 (rated at 200 amps).

Observation

Neutral service conductor is connected to a grounding bus bar instead of the neutral bus bar.

For a 200-amp service, the service entrance conductors (SEC) should be 2/0 (rated at 200 amps).

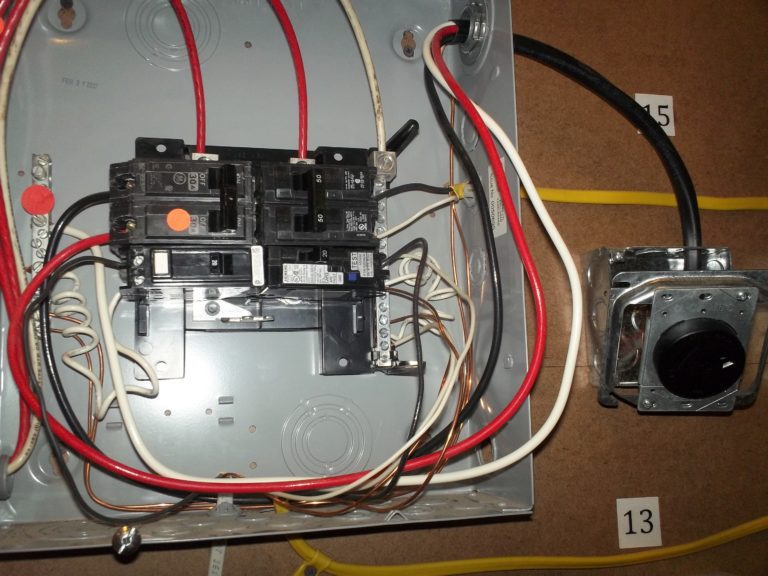

Service Panel

Observation

The service panel is not connected to a grounding electrode. No grounding electrode conductor (GEC) is installed.

The service panel should have a service grounding system installed. This would include a properly sized grounding electrode conductor (GEC) connected to the neutral bus bar at one end and to a grounding electrode (often an driven rod) at the other end.

Without a service grounding system, the electrical system is more vulnerable to lightning strikes.

Also (very important!), the equipment grounding conductors installed in branch circuits are not effective because this condition significantly reduces the ability of the overcurrent protection device (OCPD- breakers or fuses) to respond (trip/burn through) in a timely manner in the event of a short circuit or ground fault.

The service entrance conductors (SEC) are identified by tape of the wrong color where they connect to the main lugs of the service panel.

Observation

The insulation of the service entrance conductor has visible damage that exposes the wire.

Observation

The nipple is missing an insulated (plastic) bushing where it enters the service panel.

Where a raceway (like a conduit) contains circuit conductors of #4 copper or larger, and these conductors enter a cabinet, box, enclosure, or another raceway through a threaded conduit, insulated bushings are required to prevent damage from chafing against pipe threads. NEC 300.4 (G)

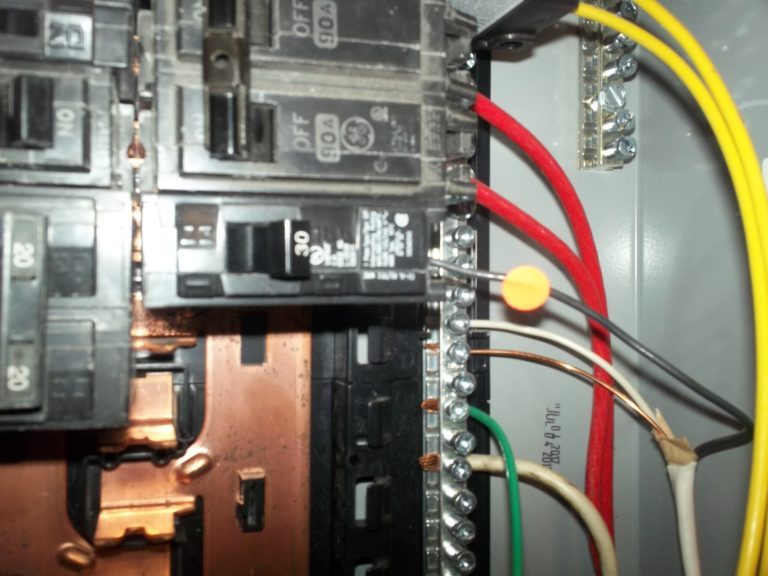

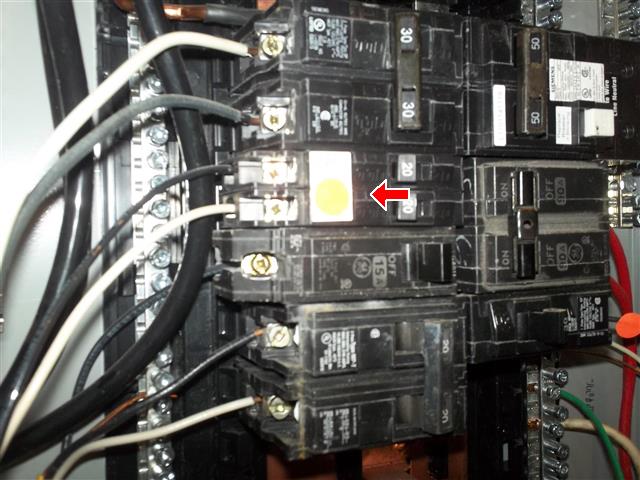

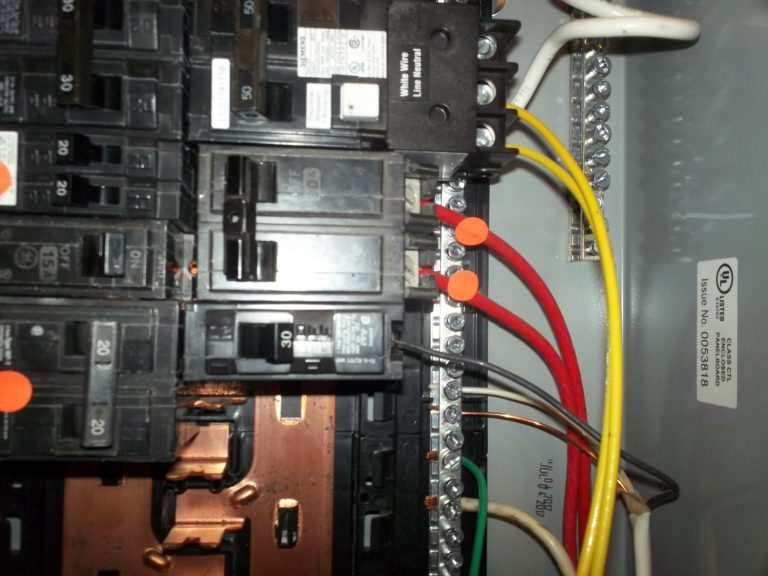

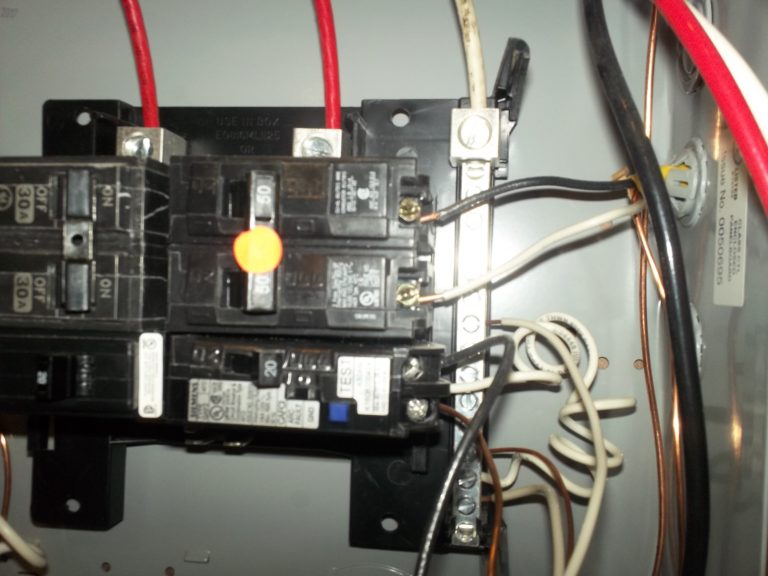

Observation

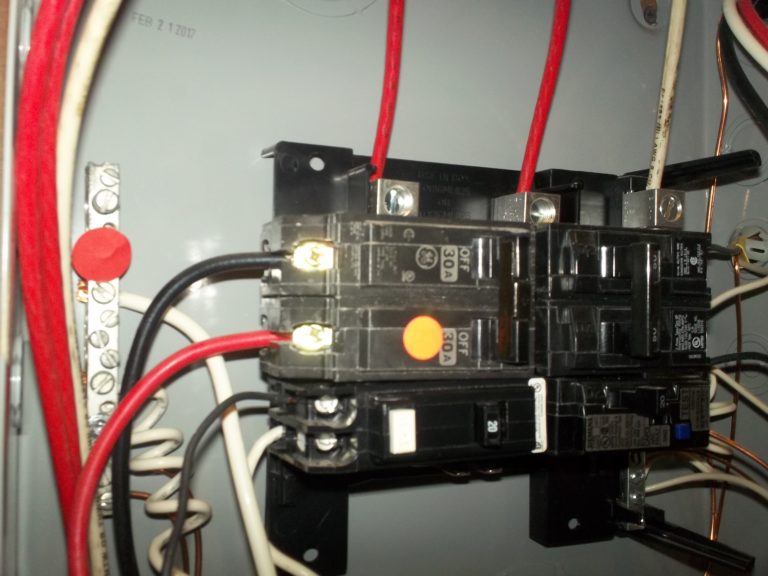

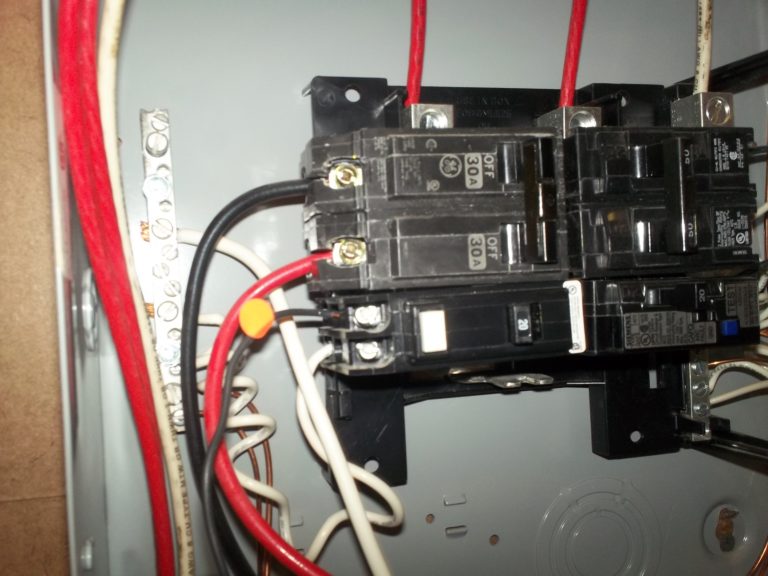

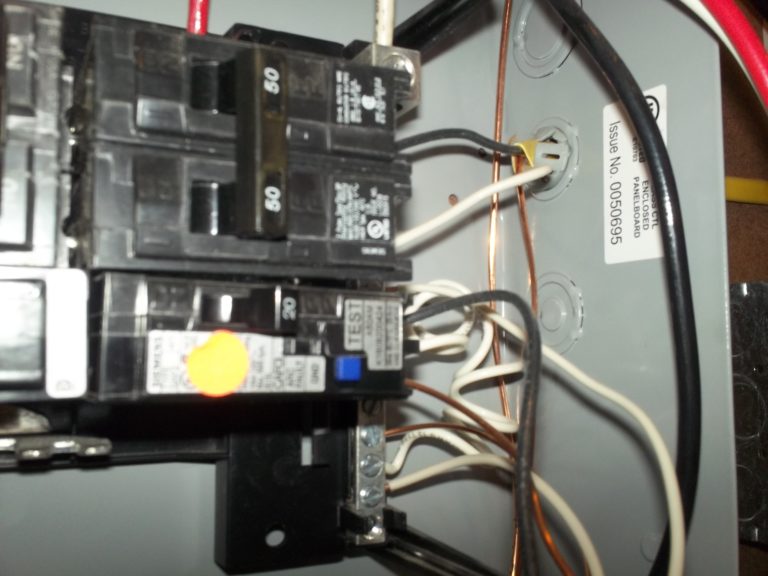

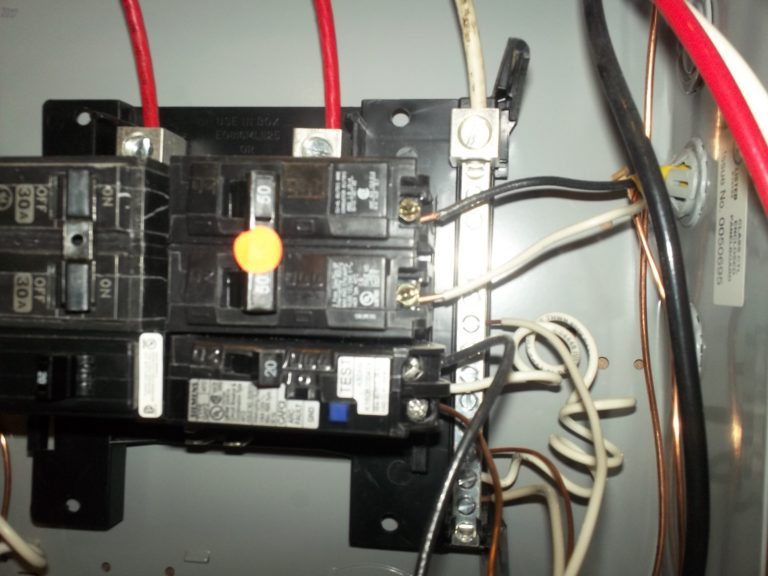

The 90-amp and 15-amp breakers are the wrong brand.

They are GE, not Siemens. The service panel is the Siemens brand. Panels should only have breakers installed for which the panel is listed, and typically breakers must be the same brand as the panel.

A 30-amp (120-volt), single-pole breaker wired with #14 copper conductor is feeding a 2-pole (240-volt) switch for a swimming pool light. The #14 conductor is undersized for this application.

The #14 conductor is rated for 15-amps maximum. A 30-amp breaker requires a minimum 10 gauge conductor.

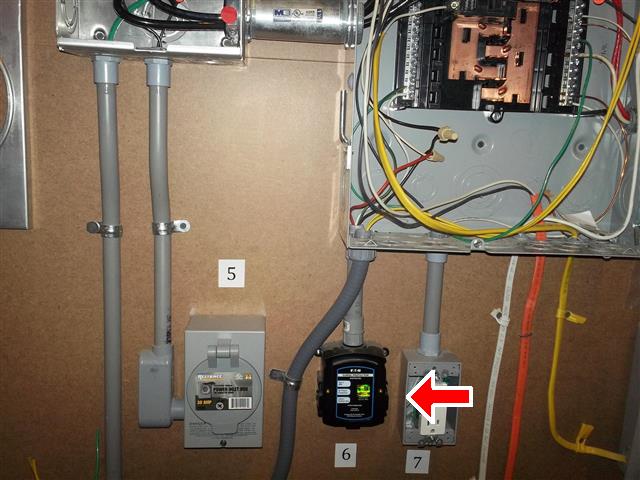

Observation

The receptacle in the weatherproof box is not ground fault circuit interrupter (GFCI) protected.

Observation

No hub cover at top of service panel.

Observation

The neutral service conductor is connected to a grounding bus bar instead of the neutral bus bar.

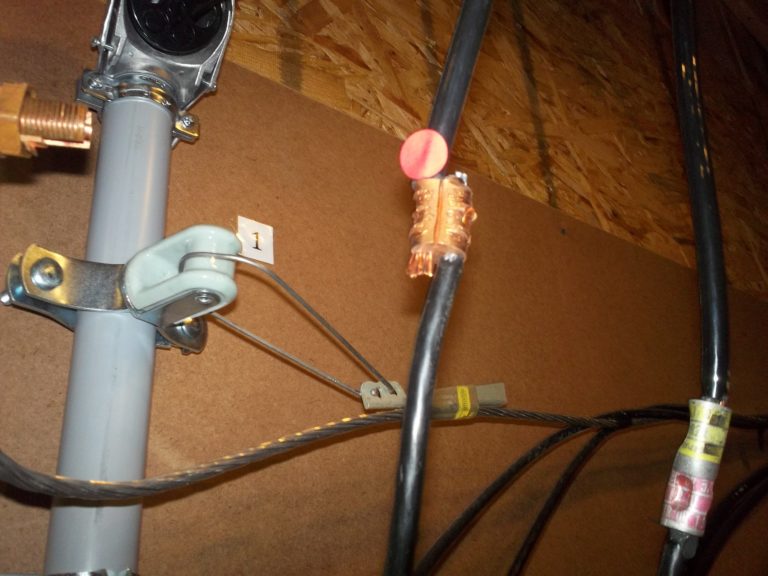

Grounding Electrodes (Driven Rod and Water Pipe)

Observation

The grounding clamp at the driven-rod grounding electrode is a water pipe clamp and its use is improper for this application.

An acorn clamp should be used. The installed water pipe grounding clamp would typically be seen in older homes in which the cold water supply pipe was used as the grounding electrode.

Some jurisdictions require installation of two rods driven to their full 8' length with a minimum separation from each other of at least 6 feet.

Observation

The grounding electrode conductor (GEC) is undersized.

The GEC should be #4 gauge minimum, not #6.

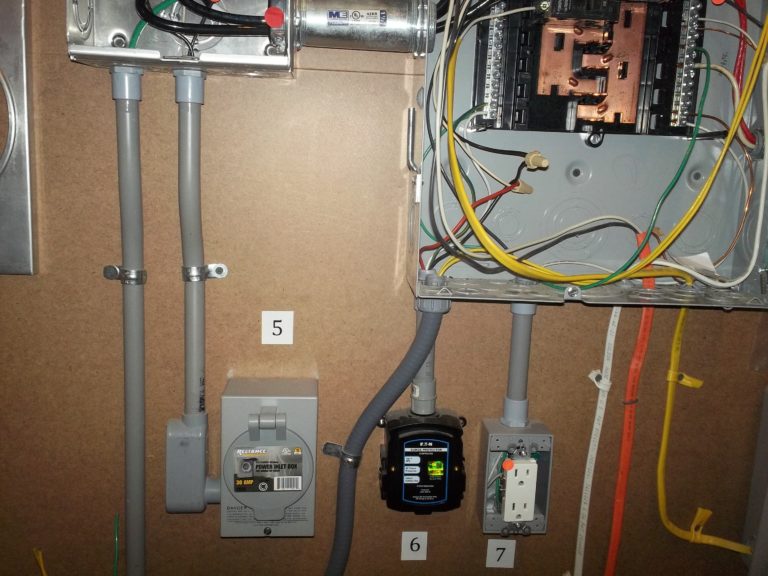

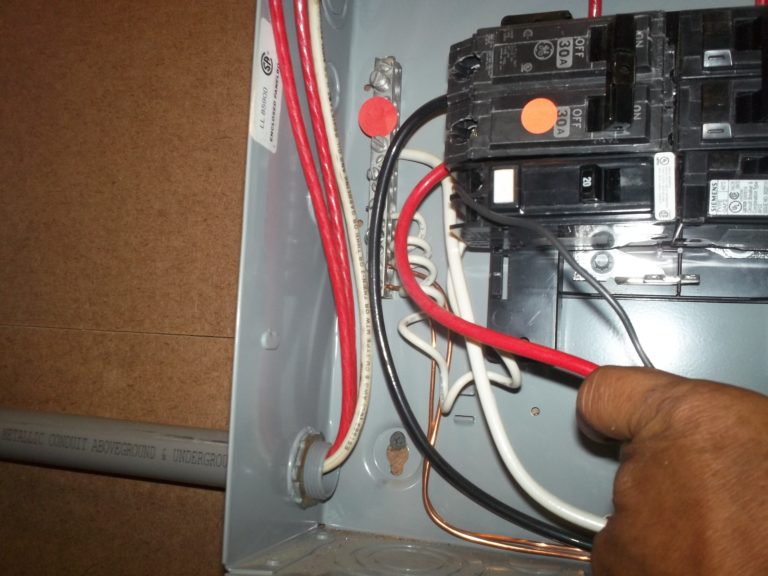

Generator Inlet

Observation

The generator inlet is not grounded.

Observation

Feeder conductors supplying power to the generator inlet are double-tapped at the load side lugs of the meter enclosure.

As a result no overcurrent protection protects the generator inlet. The generator inlet should be connected to an overcurrent protection device (OCPD)- like a breaker or fuse.

Observation

No Transfer switch or lockout from utility.

Also as a result of the lug tap at the meter, there is no lockout from the utility the service panel. A lockout tag or a transfer switch should be installed to prevent the generator from energizing utility power lines and possibly electrocuting linemen.

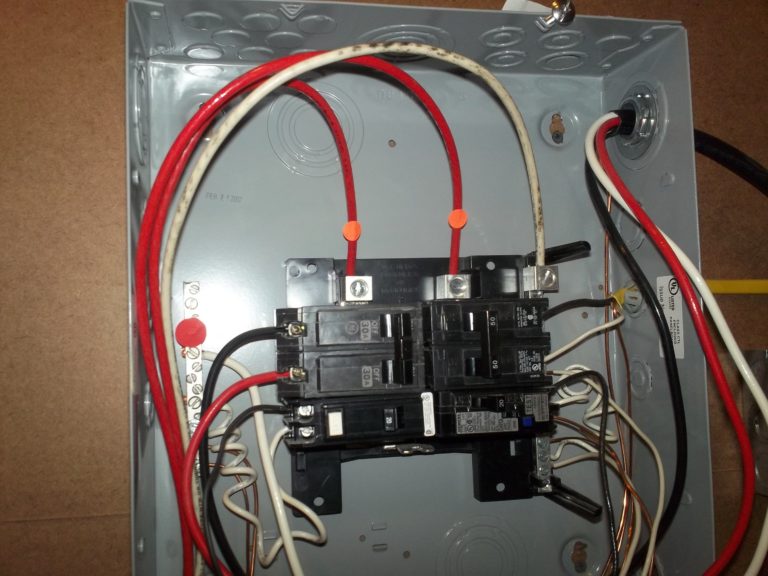

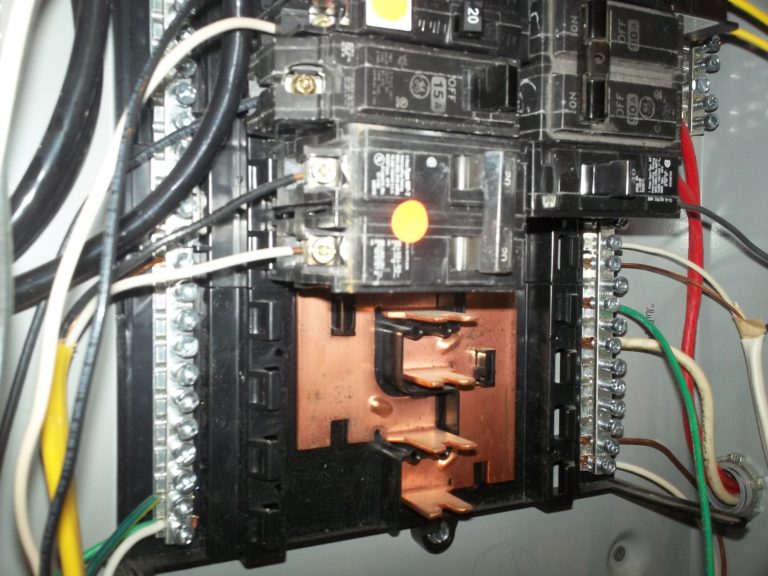

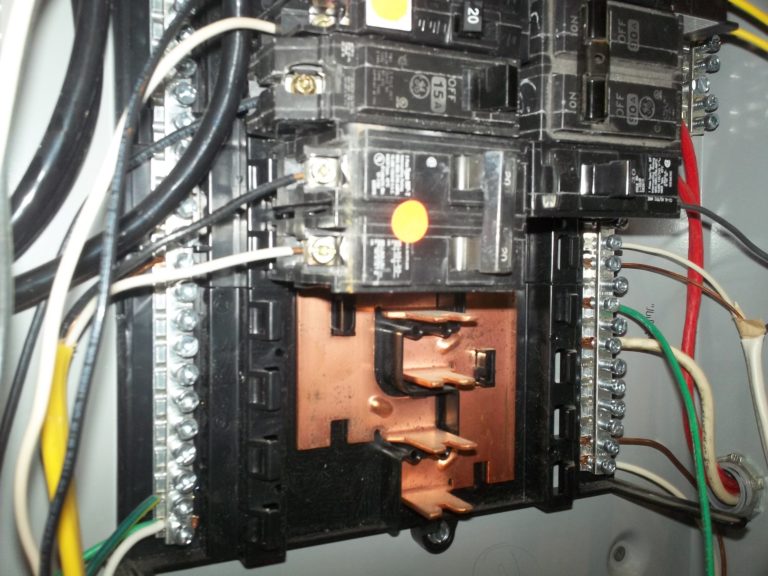

Surge Protector (Lightning Arrestor)

Observation

Surge protector fed incorrectly by two 20 amp, single-pole breakers. It should be one 20 amp, 2-pole breaker.

Observation

Pool light switch.

Observation

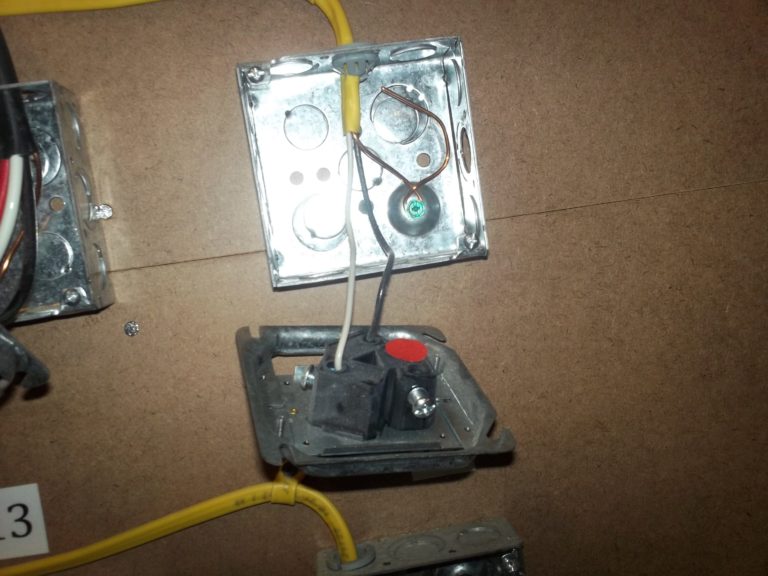

The junction box is not grounded.

Observation

The switch is not grounded.

Observation

2-pole (220 volt) switch being used instead of single-pole.

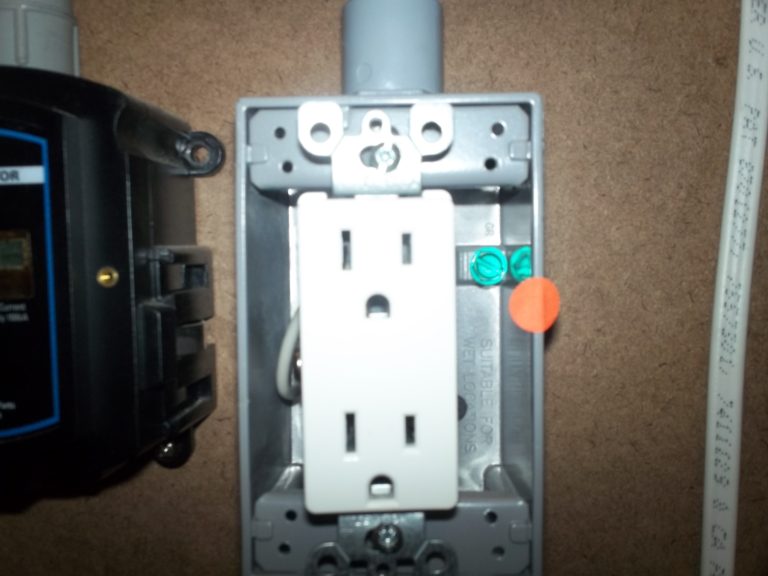

Weatherproof Receptacle

Observation

The weatherproof receptacle box has no cover. This condition may allow moisture intrusion of the box interior resulting in corrosion of electrical components and increased risk of fire.

Observation

The weatherproof receptacle box is not grounded. Because it has a 3-prong outlet installed, users may mistakenly assume that they are protected by a grounding system. This can be hazardous to those outside in a moist environment (like wet grass) using devices like electric mowers or hedge trimmers.

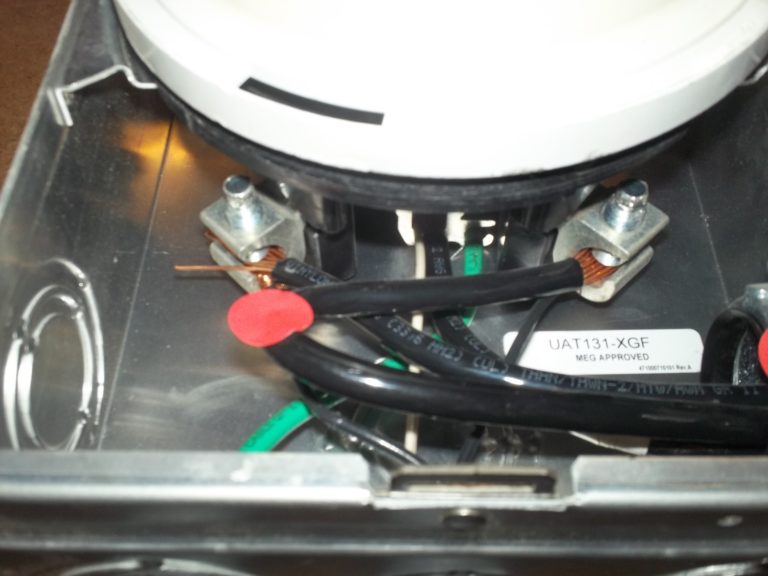

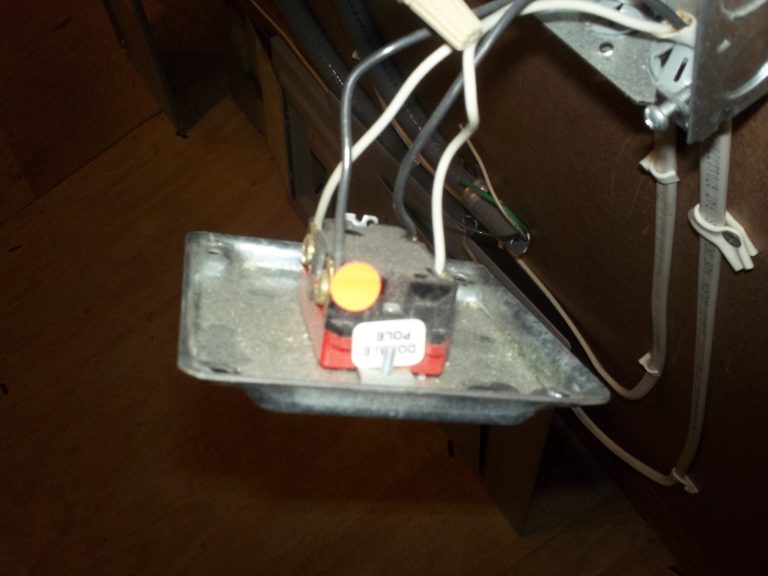

Pool Timer

Observation

The 110-volt landscape pool timer is fed with an exposed NM (non-metallic) conductor not designed for unprotected exposure to weather.

Observation

No cable connector/clamp is installed where the conductor enters the timer.

This condition can result in damage to the conductors where they past through the metal housing.

Observation

The 110-volt pool timer is fed by breakers designed for 220 volts.

Observation

The pool timer not is grounded.

Pool Light Switch

Observation

The junction box is not grounded.

Observation

The switch is not grounded.

Observation

A 2-pole, 220-volt switch is being used instead of single-pole, 120-volt switch.

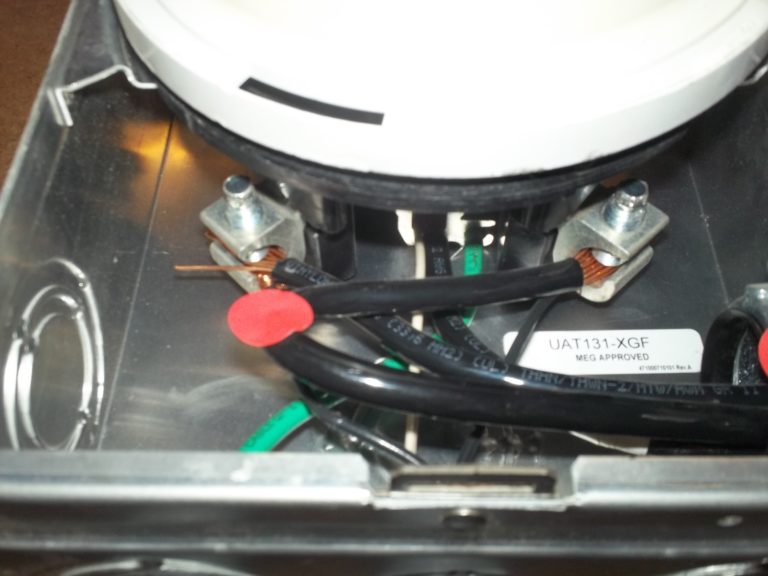

Pool Transformer

Observation

Live side being fed with 220-volt switch.

The pool transformer is 120-volt, so the switch should be rated at 120-volts.

Observation

Observation

Fed with exposed wiring.

The conductors feeding the transformer are not designed for exterior exposure and should be enclosed inside conduit.

Air Conditioning Disconnect

Observation

The 40-amp fuse is an incorrect amperage.

The fuses should both be 60 amps as listed on the label.

Observation

Fed with exposed wiring.

The conductors feeding the transformer are not designed for exterior exposure and should be enclosed inside conduit. Conductors designed for exposure to weather are typically colored grey.

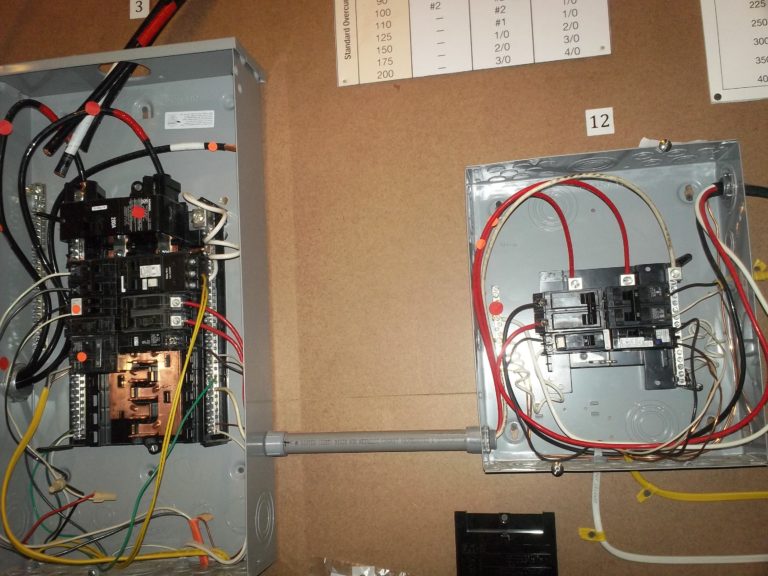

Seimens Load Center Distribution Panel

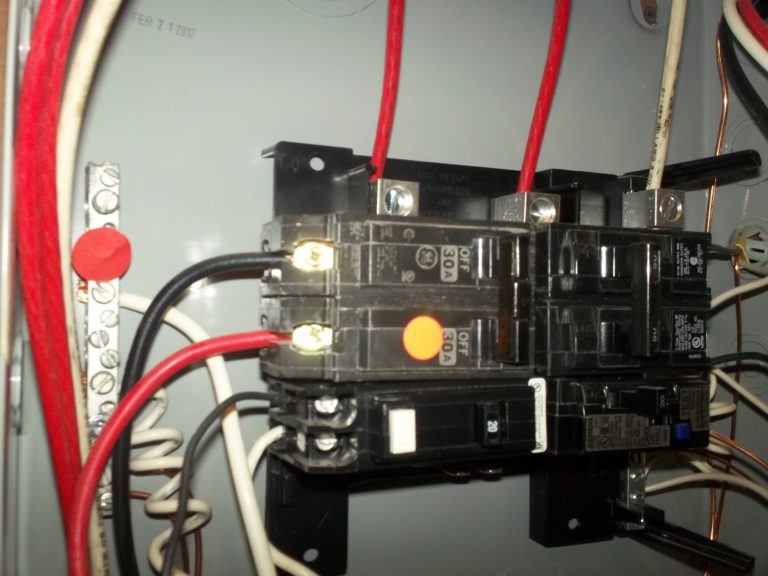

Observation

The #8 (40-amp) copper conductors feeding the 125-amp distribution (sub-) panel are undersized.

Feeders for a 125-amp panel should be minimum #2 copper (rated at 125 amps).

Observation

Undersized Conductor.

The existing 90 amp breaker is being fed by #8 copper conductors. A 90 amp breaker requires minimum #4 copper conductors.

Observation

Undersize feeder.

The 125 amp panel is being fed by #8 copper conductors, but should be fed by minimum #2 copper conductors.

Observation

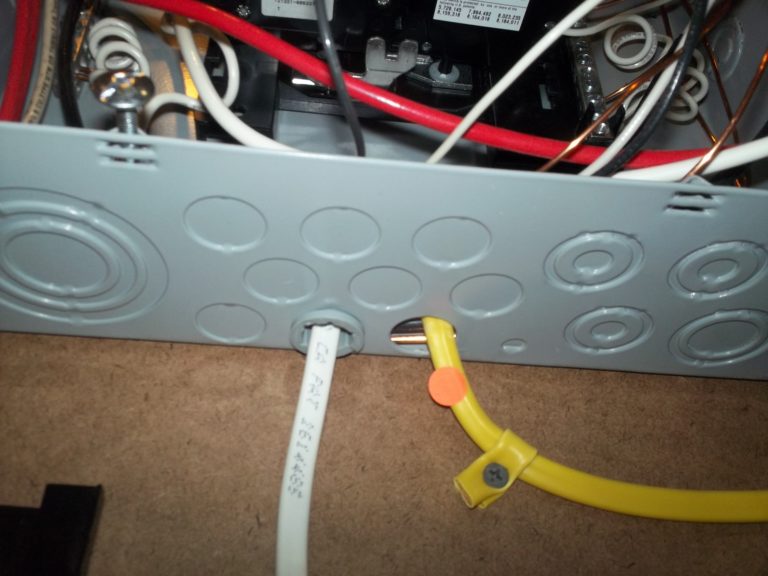

No grounding conductor from main to sub-panel.

The raceway between the service and distribution panels is PVC. To maintain electrical continuity of the equipment grounding system, an equipment grounding conductor should connect the grounding bus bar in the distribution panel to the grounding bus bar in the service panel.

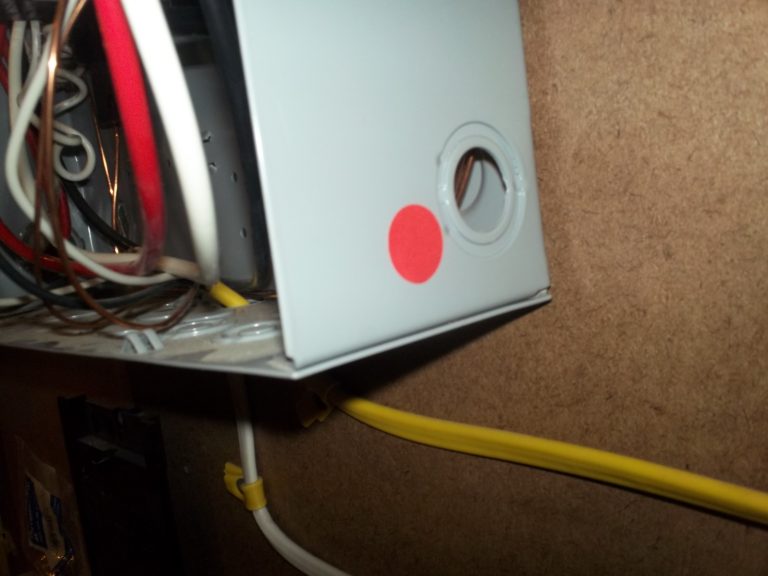

Observation

Unfilled holes (missing knockouts) are visible at the panel bottom and side.

This condition may allow pests to enter the panel and damage components.

Observation

Branch circuit conductors are not a type designed for exposure to weather.

The conductors should be enclosed in conduit, or a type of conductor should be used that is designed for exposure to weather.

Observation

Inadequate breaker and conductor size for range.

Existing is 30 amp breaker and #8 conductor. Min. requirement is 50 amp receptacle and breaker, and #6 conductors. No ground at panel.

Observation

Missing cable connector where the yellow 12 gauge conductor passes through the wall of the metal enclosure.

A connector should be installed to prevent damage to the conductor insulation.

GFCI (Ground Fault Circuit Interrupter)

Observation

The GFCI receptacle is not grounded.

A grounding conductor should connect the receptacle to the green screw at the metal box. Although it should be grounded, GFCI receptacles do not require a ground to function as intended.

Observation

14 gauge conductors are attached to a 20-amp receptacle.

The minimum conductor size for a 20-amp breaker/receptacle is 12 gauge.

AFCI (Arc Fault Circuit Interrupter)

Observation

Observation

The metal AFCI junction box is not grounded.

If the box should somehow become energized it would become a shock/electrocution hazard.

Dryer Receptacle

Observation

The metal dryer receptacle junction box is not grounded.

If the box should somehow become energized it would become a shock/electrocution hazard.

Observation

The breaker, conductor, and receptacle should be rated for 50 amps, not 30 amps.

This condition will result in nuisance tripping and is a potential fire hazard.

Observation

The existing 30-amp conductor should be #10/3 in newer or remodeled homes. In older homes with no grounding system, #10/2 is acceptable.

Range Receptacle

Observation

The metal receptacle junction box is not grounded.

If the box should somehow become energized it would become a shock/electrocution hazard.

Observation

The breaker, conductor, and receptacle should be rated for 30 amps, not 50 amps.