Garage Door Inspection Procedure

To perform an inspection of the sectional garage doors, you may follow the following inspection procedure.

The garage door is typically the largest moving object in the house, and many of its components are under high tension. Improper installation or maintenance of a garage door can create a hazardous condition that can cause serious injury or even death.

This inspection procedure covers the safest procedures that are supported by DASMA, the Door and Access Systems Manufacturers Association. If you come across a problem with the garage door, recommend that a professional inspect it to make suggestions regarding any necessary corrections.

1. Manual Release

Begin inside the garage. Have the door closed. Check for a manual release handle, i.e., a means of manually detaching the door from the door opener. The handle should be colored red so that it can be seen easily. The handle should be easily accessible and no more than 6 feet above the garage floor.

2. Door Panels

From inside the garage with the door fully closed, check the condition of the door panels. Check for damage, cracking, denting, bulging and separation of the panels.

3. Warning Labels

The garage doors should have the following warning labels:

- a spring warning label attached to the spring assembly;

- a general warning label attached to the back of the door panel;

- a warning label near the wall control button; and

- two warning labels attached to the door in the vicinity of the bottom corner brackets. Some newer doors have tamper-resistant bottom corner brackets that do not require these warning labels.

4. Springs and Hardware

Close the door and check the springs for damage. If a spring is broken, operating the door can cause serious injury or death. Do not operate the door if there is damage. Visually check the door’s hinges, brackets and fasteners. If the door has an opener, the door must have an opener-reinforcement bracket that is securely attached to the door’s top section. The header bracket of the opener rail must be securely attached to the wall or header using lag bolts or concrete anchors.

5. Door Operation

Close the door. If the door has an opener, pull the manual release to disconnect the door from the opener. Lift and operate the door. If the door is hard to lift, then it is clearly out of balance. This is an unsafe condition. Raise the door to the fully-open position, then close the door. The door should move freely, and it should open and close without difficulty. As the door operates, make sure that the rollers stay in the track.

Reconnect the door to the opener, if present. This is generally done by activating the opener until it reconnects itself to the door.

6. Spring Containment

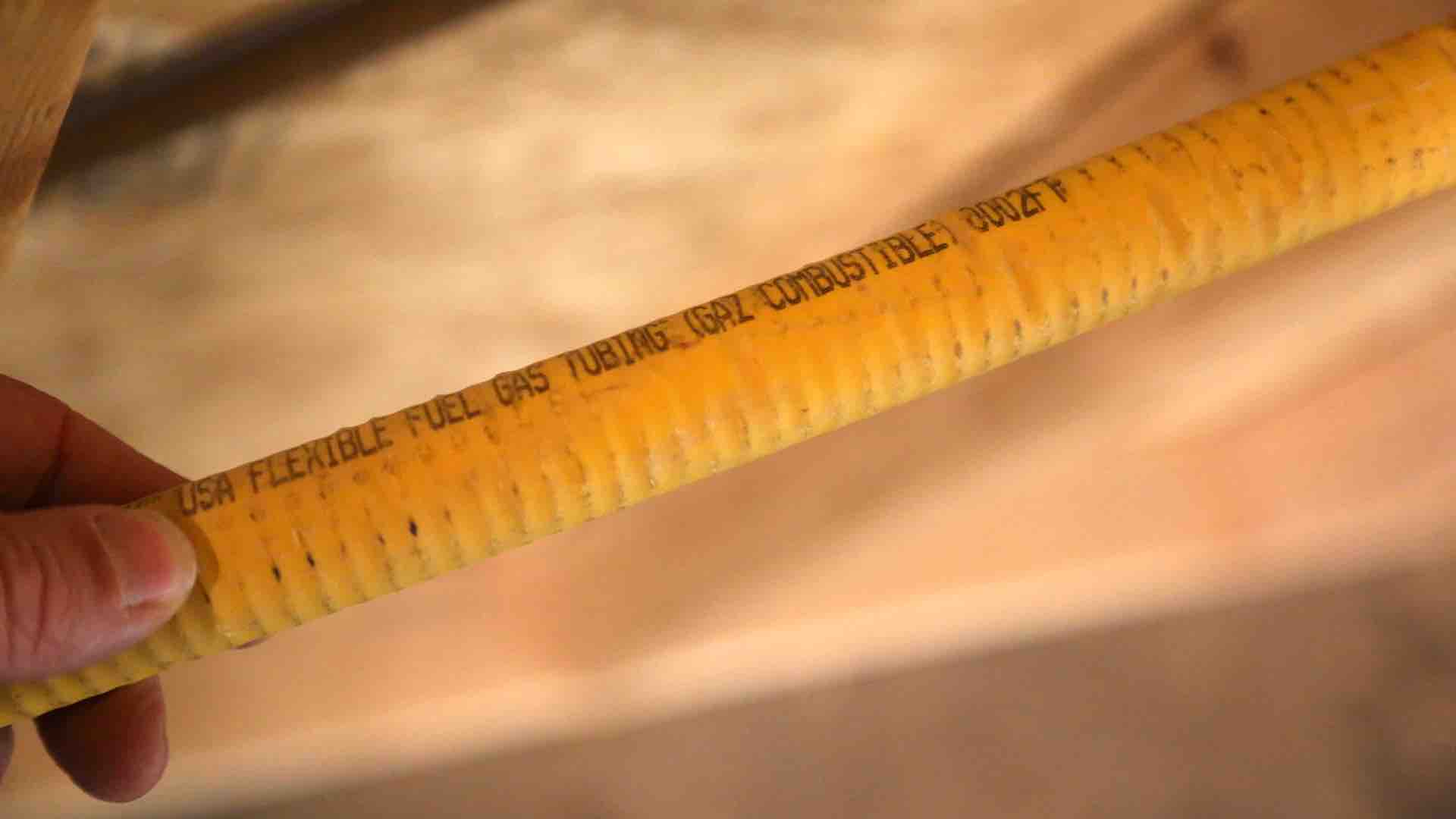

The counter-balance system is usually comprised of torsion springs mounted above the door header, or extension springs, which are usually found next to the horizontal track. When springs break, containment helps to prevent broken parts from flying around dangerously in the garage. Torsion springs are already mounted on a shaft, which inherently provides containment.

If the door has extension springs, verify that spring containment is present. Extension springs should be contained by a secure cable that runs through the center of the springs.

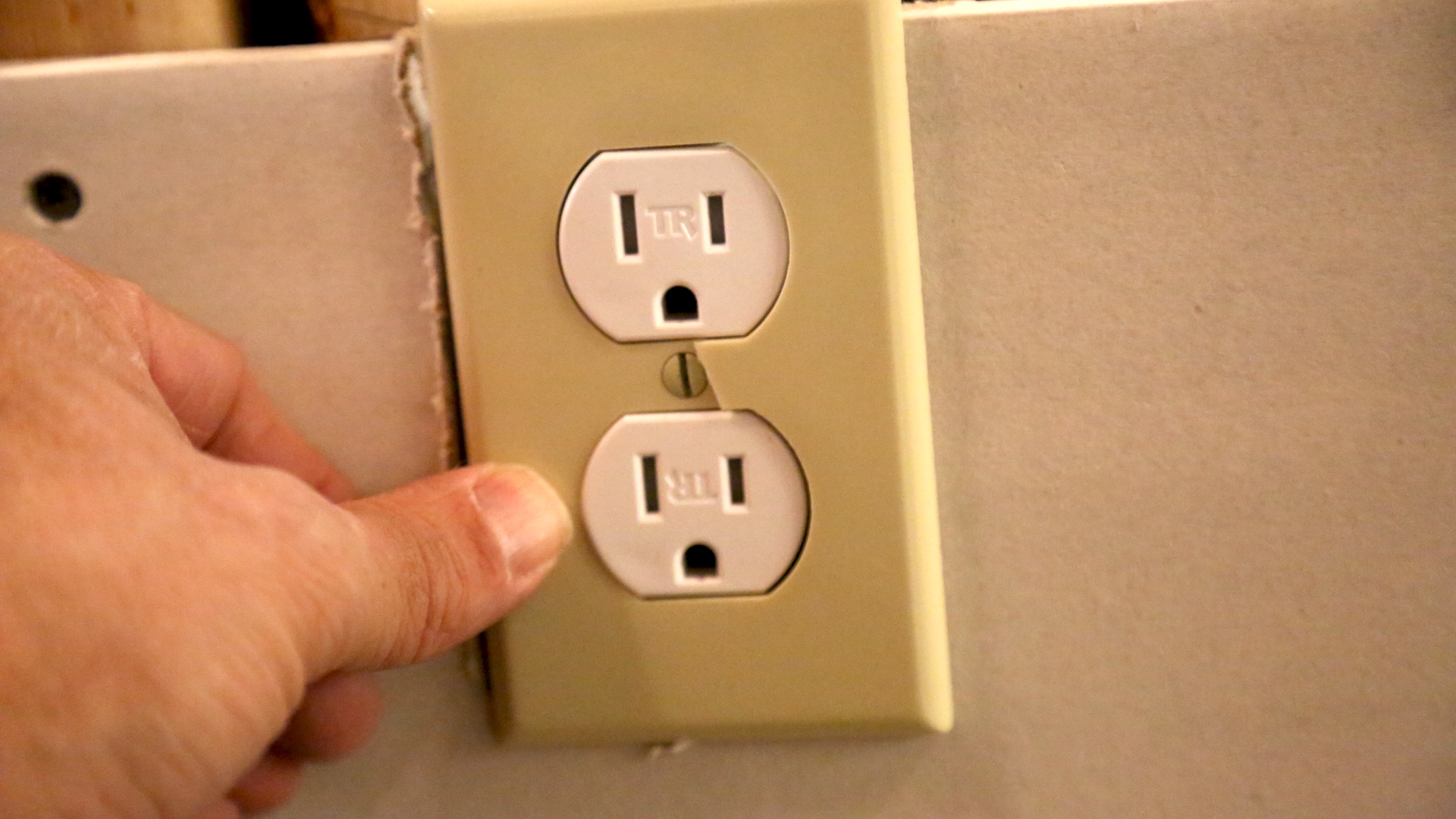

7. Wall Push Button

The wall button should be at least 5 feet above the standing surface, and high enough to be out of reach of small children. Press the push button to see if it successfully operates the door.

8. Location of the Photo-Electric Eyes

Federal law states that residential garage door openers manufactured after 1992 must be equipped with photo-electric eyes or some other safety-reverse feature that meets UL 325 standards.

Check to see if photo-electric eyes are installed. The vertical distance between the photo-eye beam and the floor should be no more than 6 inches.

9. Non-Contact Reversal Test

Standing inside the garage but safely away from the path of the door, use the remote control or wall button to close the door. As the door is closing, wave an object in the path of the photoelectric eye beam, such as a 2x4. The door should automatically reverse.

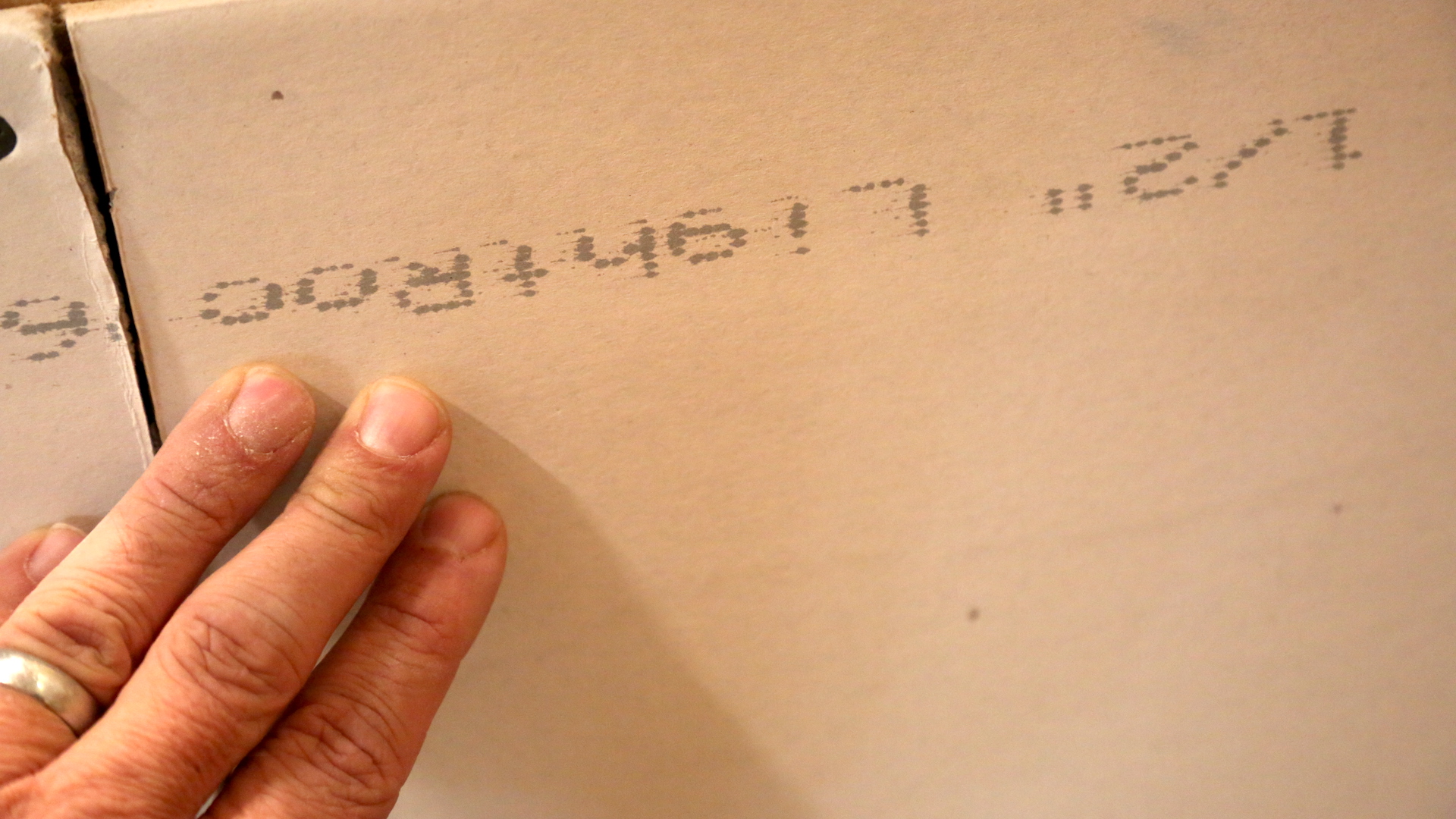

10. Garage Door Labels

Look for labels at the garage door.

The labels provide helpful safety information. Many garage door labels were created using the guidelines of the ANSI-Z535 series of standards regarding the content and format of product safety labels.

The descriptions of the following labels were created by DASMA:

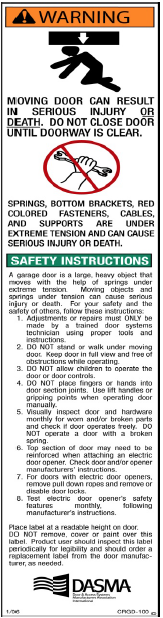

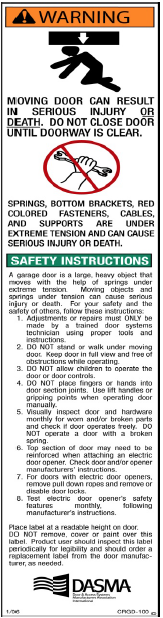

CRGD-100, Garage Door Safety Instructions Safety Label:

This label warns of hazards associated with a garage door. A list of instructions is also given pertaining to safe operation of a garage door. This label should be placed at a readable height on the door.

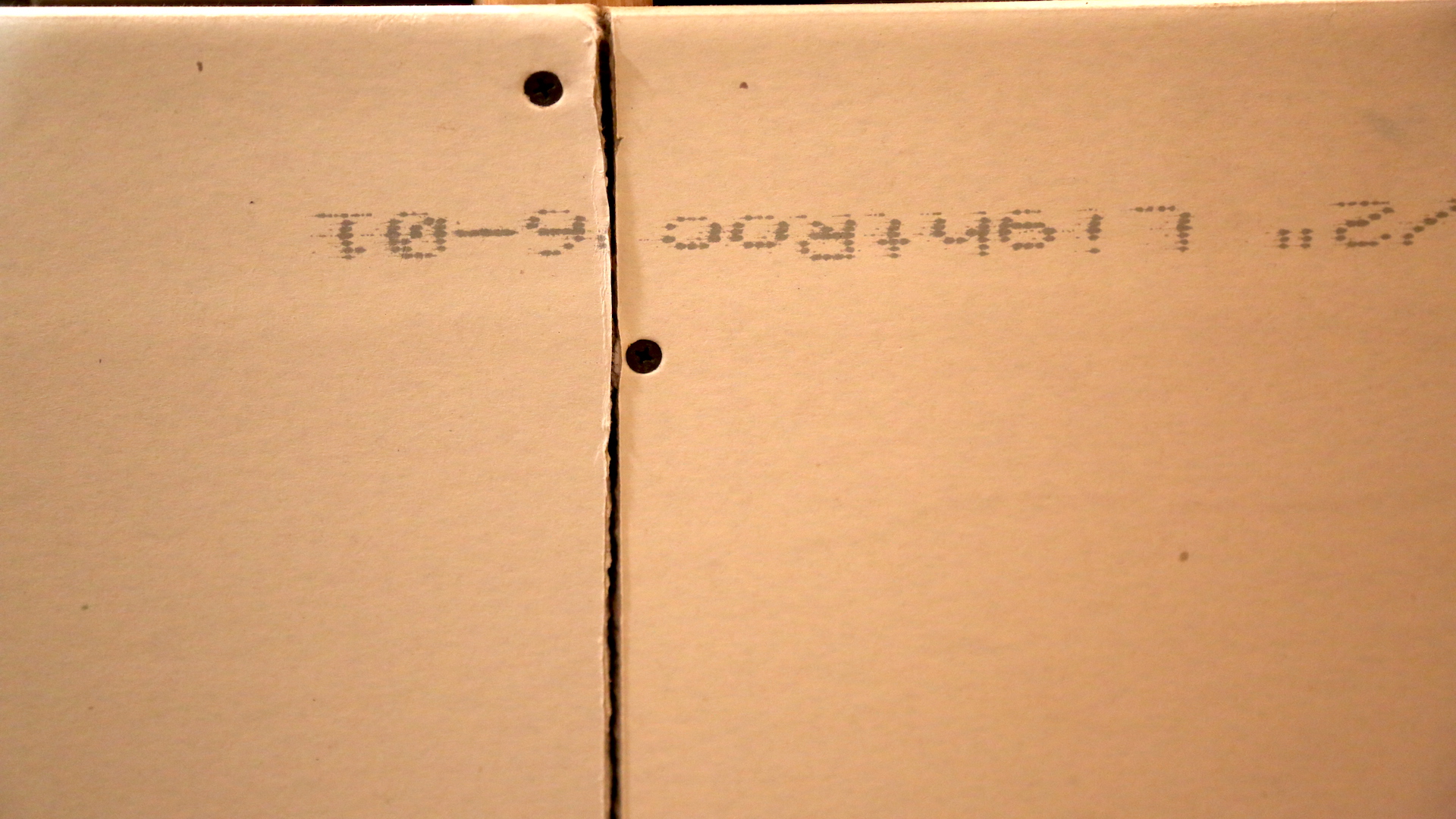

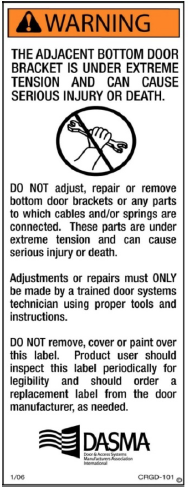

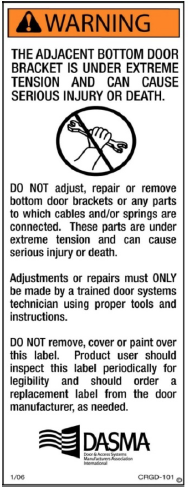

CRGD-101, Garage Door Bottom Bracket Safety Label:

This label warns that a garage door's bottom bracket is under extreme spring tension. This label should be placed adjacent to a garage door's bottom bracket.

CRGD-102, Garage Door Springs Safety Tag:

This two-sided tag warns that garage door springs are under extreme tension. This tag should be affixed directly to a garage door spring assembly such that it does not interfere with spring function.

RDD-203, Rolling Door Annual Inspection & Drop Test Record Label: