Mastering Roof Inspections: Metal Roofs, Part 5

by Kenton Shepard and Nick Gromicko, CMI®

The purpose of the series “Mastering Roof Inspections” is to teach home inspectors, as well as insurance and roofing professionals, how to recognize proper and improper conditions while inspecting steep-slope, residential roofs. This series covers roof framing, roofing materials, the attic, and the conditions that affect the roofing materials and components, including wind and hail.

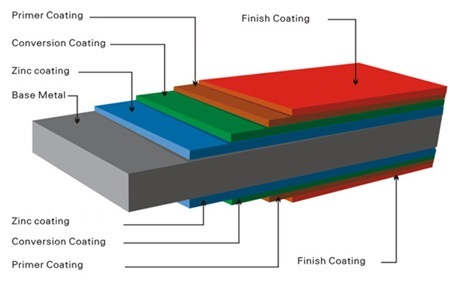

Barrier coatings function by depriving metal of the catalyst it needs to corrode, which is moisture. Paints are a good example of barrier protection.

Paints are applied at coil-coating facilities where the metal is cleaned and etched to ensure good bonding. Then it is coated with paint and baked.

The process for applying barrier coatings, such as primer and paint, are similar to the process for applying metal coatings in that the untreated steel coil revolves as the steel travels through a series of mechanical apparatus that perform different functions.

Paint films have microscopic defects that allow moisture, salt, acid rain, and other corrosive agents to pass through and encourage corrosion of the underlying metal. Even if there are no defects in the coating, all paints are semi-permeable membranes through which corrosives can slowly migrate and reach the metal surface.

Types of Paint

The three main paint-type coatings used in the North American metal roofing industry are acrylic emulsions, polyesters and fluoropolymers.

Acrylic Emulsions

Water-based acrylic emulsions are one of the most common and environmentally friendly coatings. Their application includes a primer and top coat. Acrylics don’t carry warranties for fading or chalking.

Polyesters

The polyester group includes a number of formulations which, like acrylics, are generally low-cost finishes and subject to fading and chalking over time.

Fluoropolymers

Fluoropolymers are high-quality paints that are highly resistant to solvents and acids, and have properties similar to Teflon®.

Granular Coatings

Stone coatings are similar to asphalt shingle granules and are used on shake, tile and slate profiles. Stone coatings may develop the same moisture-related microbial problems as asphalt shingles, such as algae, lichen and moss.

The types of metal shingles you see in the photos above are extremely difficult to walk without damaging. You can see the result in the photo below. When you inspect this type of roof, look for damage from footfall, and mention it in your report. If you fail to report this type of damage, you may be blamed for it.

Reflective Pigments

**************************************************

Learn how to master a roof inspection from beginning to end by reading the entire InterNACHI series: Mastering Roof Inspections.

Take InterNACHI’s free, online Roofing Inspection Course

Mastering Roof Inspections

Roofing Underlayment Types

Inspecting Underlayment on Roofs

Fall-Arrest Systems

Roofing (consumer-targeted)

More inspection articles like this