Mastering Roof Inspections: Flashing, Part 4

by Kenton Shepard and Nick Gromicko, CMI®

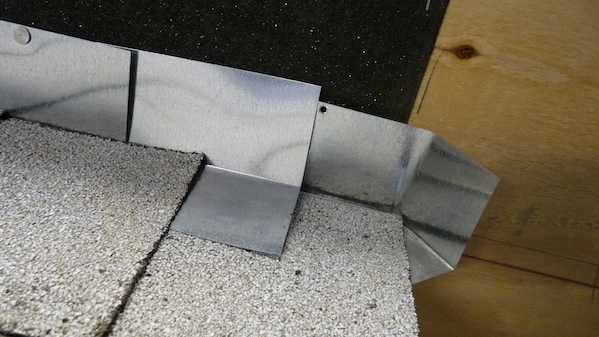

KICKOUT FLASHING

Where a wall extends past a roof eave, sidewall flashing will stop at the edge of the eave, since this is where the sidewall condition ends. At the lower roof edge, sidewall flashing should extend out from the wall at least a couple of inches, and be bent to an angle.

This detail is called “kickout flashing,” and its purpose is to prevent runoff from entering behind the exterior wall covering where the flashing ends.

Kickout flashing is required regardless of the type of roof-covering material or exterior wall covering, with the exception of brick or concrete block.

Courtesy of Mark Thorman

Sometimes, it is easy to spot the missing kickout flashing. This well-watered plant is being watered from inside the wall.

A few manufacturers do specify size, such as the manufacturer of this synthetic stucco. Realistically, you won’t know about size requirements. Just check to make sure that kickout flashing is installed where it should be, and check to make sure that it looks like it will do the job -- that job is preventing moisture intrusion of the wall.

Pre-formed kickout flashing is available, but kickout is usually made on site using sidewall flashing.

**************************************************

Learn how to master a roof inspection from beginning to end by reading the entire InterNACHI series: Mastering Roof Inspections.

Take InterNACHI’s free, online Roofing Inspection Course

Mastering Roof Inspections

Roofing Underlayment Types

Inspecting Underlayment on Roofs

Fall-Arrest Systems

Roofing (consumer-targeted)

More inspection articles like this