Mastering Roof Inspections: Asphalt Composition Shingles, Part 54

by Kenton Shepard and Nick Gromicko, CMI®

The purpose of the series “Mastering Roof Inspections” is to teach home inspectors, as well as insurance and roofing professionals, how to recognize proper and improper conditions while inspecting steep-slope, residential roofs. This series covers roof framing, roofing materials, the attic, and the conditions that affect the roofing materials and components, including wind and hail.

Jurisdictional Requirements

The type of fasteners that can be used on new construction may be limited by jurisdictional requirements. Areas that commonly experience hurricane-force winds typically don't allow staples to be used.

Fastener Types

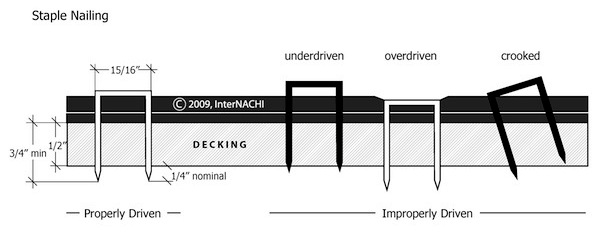

The type of fastener used to fasten the shingles is especially important for resisting wind uplift and pull-through. Fasteners for asphalt shingles should be roofing nails or staples. The head of a roofing nail and the crown of a staple are the parts that actually hold the shingles in place. The minimum width for the staple crown is 15/16-inch.

Fastening shingles with staples may void the manufacturer’s warranty against wind damage.

Both nails and staples have sufficient strength to resist the small uplift load on the fasteners as long as the adhesive strips are fully bonded. If staples are properly installed, they offer close to the same resistance to wind as nails.

Staples

The problem with staples is orientation. As an installer uses an air-compressor staple gun, his natural tendency is to rotate his body. Unless he also rotates his wrist at the same time, the orientation of the staple crowns will reflect this rotation.

Properly installed, stapled shingles will usually withstand wind speeds of up to 60 mph. Upgrading the fastening system requires re-fastening the shingles with roofing nails. The shingles may need to be hand-sealed afterward because the adhesive bond may not re-seal adequately.

Nails

Some shingle manufacturers specify that their shingles be fastened with nails. Nails should be corrosion-resistant, wide-head roofing nails of the proper length. Corrosion-resistant nails can be made of galvanized steel, copper, aluminum or stainless steel.

Proper Fastener Installation

Fasteners should not be over-driven, which will cause them to cut part-way through the shingle and lower its wind resistance. They should also not be under-driven, which will cause the protruding nail head to eventually wear a hole through the overlying shingle.

Fasteners driven at an angle can cause both problems, depending on how deeply they’re driven.

Fastener Placement

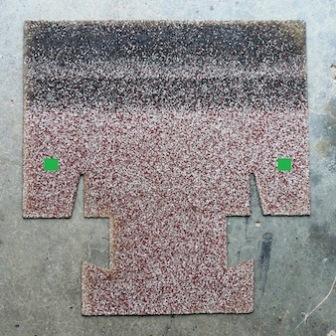

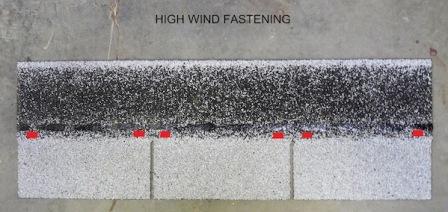

Fasteners should be placed according to the manufacturer’s instructions. Generally, they should be installed below the adhesive strip, equally spaced across the shingle, and placed in slightly from the ends, as shown in the two photos above.

T-lock shingles have their own requirements for fastener placement.

Shingles in areas designated as high-wind areas should have additional fasteners installed at the two inner positions, as shown in the two photos above.

Heavy architectural shingles often have different fastening requirements. The fastener placement may vary by slope rather than by wind designation.

Standard-slope fastening

Steep-slope fastening

The Holding Power of the Substrate

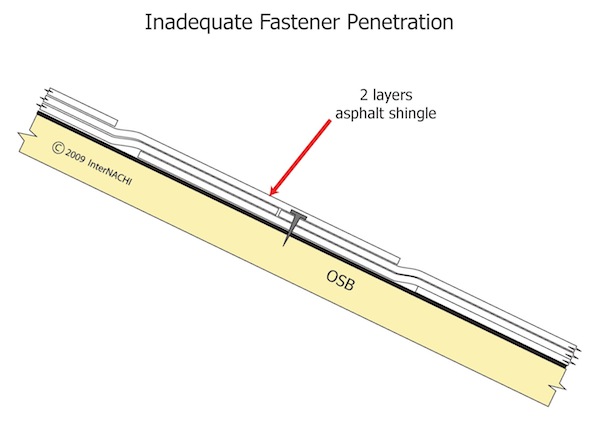

The holding power of the substrate affects the holding power of the fasteners. Decayed or rotten sheathing will not anchor fasteners well.

Inadequate Penetration

**************************************************

Learn how to master a roof inspection from beginning to end by reading the entire InterNACHI series: Mastering Roof Inspections.

Take InterNACHI’s free, online Roofing Inspection Course

Mastering Roof Inspections

Roofing Underlayment Types

Inspecting Underlayment on Roofs

Fall-Arrest Systems

Roofing (consumer-targeted)

More inspection articles like this